Bruno Johnson and Trevor Cullen explain how the first certified KNX IoT product, an environment sensor, can be used to monitor indoor air quality in a beauty salon, as required by legislation.

Beauty salons often suffer from poor indoor air quality (IAQ). Airborne contaminants from volatile organic compounds (VOCs) such as bleach with peroxide, acetone and dihydroxyacetone (DHA) – all found in beauty products – can put both staff and clients at risk. The UK and EU have regulations relating to such hazardous substances which require employers to assess risks, prevent or control exposure, and provide staff with information, instruction and training. Moreover, the EU Energy Performance of Buildings Directive (EPBD) will soon require all commercial buildings to monitor IAQ.

In order to assess the risks, prevent excessive exposure and help improve staff training, as required by legislation, communications company Cascoda assisted distributor Innovelec in installing a Cascoda environment sensor to monitor IAQ in a beauty salon called Diffusion, in Berkhamsted, Hertfordshire, UK.

This is no ordinary sensor, however. It is the first certified KNX IoT product.

KNX IoT

KNX IoT uses Internet protocol (IP) as the communication medium and is backward-compatible with traditional KNX twisted-pair (TP). As such, Cascoda implemented KNX IoT on its certified wireless Thread technology. Thread is a low-power wireless mesh network which can cover a large area and support dozens of devices. Other advantages of Thread include ultra-low-power and the support of sleep modes.

Planning and design

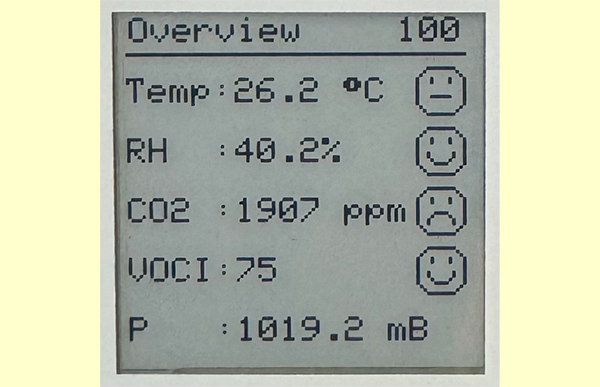

The Cascoda KNX IoT Environment Sensor measures environment variables including room temperature, relative humidity, CO2, atmospheric pressure and VOC index. This set of measurements gives a good overview of what is a safe environment in which to work.

The device is battery operated; hence no wires are required for its installation. This means that little planning is needed in the design of the system other than placement of the environment sensor in an appropriate location. This must be at breathing height; away from windows, doors and ventilation openings; not close to individual working spaces; and close to where hazardous liquids are stored (in order to detect spillage).

Installation and operation

Once a suitable location had been established, the installation took 10 minutes, plus a further 15 minutes to configure. Since no invasive drilling or wiring was needed, the installation was non-disruptive and could take place during normal business hours.

Local feedback

The environment data values are displayed on a local display, which also has ‘smiley’ indicators stating whether the values are within safe, marginal or poor operating levels.

Remote monitoring

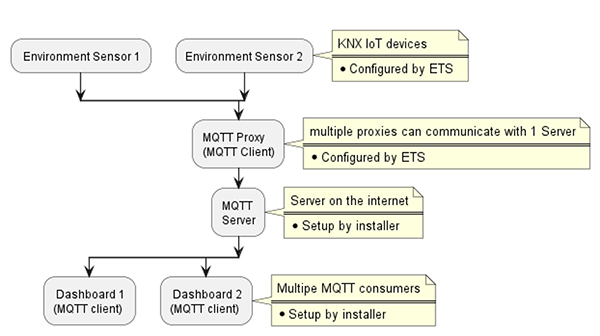

The environment sensor is wirelessly connected to the Cascoda KNX IoT Hub running a cloud backhaul known as MQTT. The Hub’s MQTT proxy translates KNX IoT data from the environment sensor and pushes it to a server either locally or over the Internet. The data can then be visualised on computers or apps.

The system is configured by ETS6.3. The data points of the environment sensor are connected via group addresses to the data points of the MQTT server. To configure the MQTT proxy, the connection information and credentials of an MQTT broker must be provided. For this setup, a HiveMQ cloud-based MQTT platform was used.

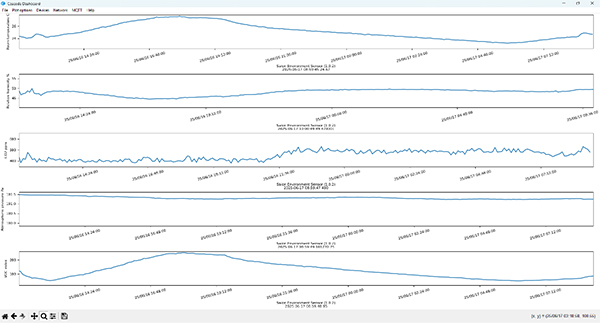

To receive the measurements, an MQTT client can be used. This means that the environment sensor data can easily be integrated with existing systems. To show the real time data, Cascoda built an MQTT client, also known as a dashboard.

Benefits of the system

Deploying a KNX IoT system in this project had a number of advantages over wired systems. It resulted in a much faster install time and lower installation costs thanks to wireless protocols. It required minimal cabling, as wireless mesh networks significantly reduce the need for invasive wiring. It also meant a quicker deployment, as wireless systems can be installed more quickly, with less disruption to operations.

More generally, this technology is ideal for retrofitting, which is especially advantageous where running new cabling is difficult or expensive. It also offers native integration with smart systems thanks to IP connectivity; cloud integration for improved data collection and processing; and a

dashboard for improved visualisation and alerts. The analytics available help in identifying inefficiencies for improved decision making.

The system meets EPBD Compliance and the Retrofitting Mandate requirements. EPBD readiness means that buildings must be equipped with systems that monitor IAQ, and retrofit requirements mean that by 2030, many existing buildings must be upgraded.

Conclusion

This IAQ monitoring solution for a beauty salon consists of KNX IoT devices sensing indoor air quality, and a KNX IoT Hub collecting the data from the environment sensor and pushing it to a cloud server. It has been running since late May 2025.

The client was surprised that the installation was made so quickly and that there was no need to disrupt operations during installation. After becoming familiar with the dashboard, the client identified certain practices that led to spikes in VOCs and CO2, and began to implement processes to mitigate these. As a result, staff have reported less fatigue and fewer headaches, especially later in the working day.

In time, the data collected will prove that the salon is fulfilling current and future health and safety guidelines. More pertinently though, the system provides the client with the tools to improve the salon’s air quality, thereby raising client satisfaction and staff wellbeing.

Equipment list

Cascoda KNX IoT Environment Sensor

HiveMQ cloud-based MQTT platform

Bruno Johnson is the CEO of Cascoda Limited, a communications company that manufactures chips, modules and devices to unlock smart building KNX IoT connectivity. Trevor Cullen is the Managing Director of Innovelec, an electronics distributor that combines in-depth knowledge and industry experience to provide individual project solutions.