Andy Ellis looks at the variables involved in designing a heating system using weather compensation for maximum comfort and efficiency.

It seems that the weather is becoming less predictable. In recent years, the number of days at sub-zero temperatures which have occurred annually within the UK, for example, has fluctuated greatly. In 2020, the number of days per month with air frost peaked in March, at 7.9 days. In 2021, it peaked in January, with 18.5 days (source: Statista). A frost day is any day with a minimum temperature below zero.

In our search for efficiency and comfort, we need to mitigate these fluctuations, and we can do so using weather compensation.

What’s the difference between weather compensation and simply relying on a thermostat?

Normally, the heat output of a heat source is reduced in summer months and increased as the weather gets colder. During periods of cold weather there are greater losses throughout the building and thus a greater amount of energy is required in order to maintain the set point temperature inside.

When using weather compensation, we are primarily concerned with customer comfort by maintaining the internal temperature of the house as close as possible to the set point for extended periods of time. And as a consequence of compensating, most systems will be more efficient.

Room (or load) compensation using PI (proportional integral) or PWM (pulse width modulation) methods and individual room thermostats, is an excellent way of maintaining even set point temperatures, but it tends to be reactive and is not influenced by outside temperatures.

Weather compensation on the other hand, is proactive. It takes outside temperature readings and adjusts the boiler output before the house has had a chance to cool down. Of course the subject is not a simple one and involves a number of variables, some of which, in reality, are hard to determine. These include:

• Rate of heat loss out of property – how well is the building is insulated?

• Emitters – is the heat being emitted into the property quickly (radiators) or slowly (underfloor)?

• Air tightness and air flow – how air tight is the property and how well air is moved around? Properties with mechanical ventilation and heat recovery (MVHR) will have a far more even heat distribution.

• Temperature difference – in the depths of winter when temperatures go below freezing, the temperature difference between inside and outside will be greatest and thus more energy is required to heat the building.

• Usage pattern – is the property used on a random basis? If so, heating from a low extreme to a high temperature is far less preferential than maintaining a constant temperature.

• Type of heat source – is it a gas boiler, oil boiler or heat pump? The latter will be more efficient at different loads and, in the case of air source heat pumps (ASHPs), at different external air temperatures.

• Timers active – a hot water timer or heating timer (including mode changes) will affect when the boiler is active; in the case of an ASHP, maximum efficiency may be achieved during the day when outside air temperatures are warmer.

• Matching temperature demands and achieving maximum efficiency – this could be a case of juggling hot water demand at 60oC, followed by, say, underfloor heating demand at 45oC.

• Heating system design – low loss header, thermal store, pump speeds, mixer valves – all will make a difference to how the system can operate.

As a rough guide, changing thermostatic controls from on/off to PI could result in an increase in efficiency between 5-15%. By adding weather compensation, further increases can be achieved.

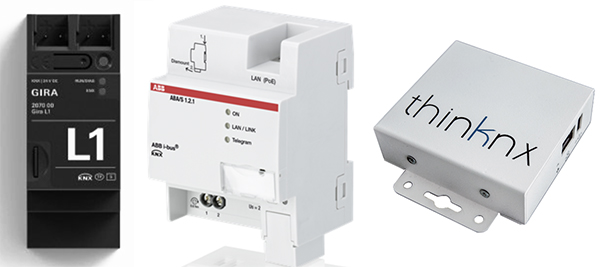

Implementing weather compensation using KNX

The use of KNX to control weather compensation requires careful consideration at the design stage. For smaller installations, implementing the boiler manufacturer’s weather compensation functions may be the simplest and most cost-effective solution.

A KNX/OpenTherm interface will give installers access to outside temperature measurement via the boiler and provide feedback of boiler flow temperatures as well as providing an overall means of managed call for heat, for both heating and hot water. As the heating and hot water system grows in size and complexity, then the versatility of KNX comes into its own. Any number of different input and output devices can be designed into the system along with the ability to provide monitoring for problem-solving and longer-term maintenance and diagnostics.

Heating design will require elements of logic, and many KNX devices now come with basic logic functions. However, in larger, more sophisticated systems, where flow temperatures can be manipulated directly, then Proportional Integrated Derivative (PID) logic functions may be required and thus a separate dedicated logic controller too.

Like all projects you will need to analyse the returns. In the case of weather compensation, this is not easy, as you are dealing with so many unknowns. However a simple payback calculation should quickly give you a reference as to whether weather compensation is worthwhile in your given situation.

Conclusion

In a well-designed system, weather compensation will ensure that the property remains at a comfortable temperature throughout the winter and will deliver more efficient operation. However, given the number of variables, each installation will be bespoke. The challenge lies with quantifying the gains in efficiency over and above a ‘non-compensated’ system.

One of the added advantages of using KNX is that you will have access to all the information on the KNX bus. By implementing monitoring and graphing software, longer term trends and problems can be identified. Ultimately, you should think carefully before implementing weather compensation, and be even more cautious about what you can claim to achieve.

Andy Ellis is the founder and managing director of Household Automation Ltd, and its sister company Knxion Ltd, providers of building automation consultancy, design, installation and aftercare services to clients who are involved in building residential and commercial properties.